In outdoor settings, standard labels are simply not enough. Exposure to UV rays, rain, snow, wind, chemicals, and temperature extremes can lead to fading, peeling, cracking, or complete label failure.

At Label-Aid Systems, Inc., we specialize in delivering high-performance, weatherproof, and fade-resistant labels that remain legible and firmly affixed in even the harshest environments. Whether your labels need to withstand years of sun exposure on a utility pole or daily washdowns outdoors, choosing the right materials, adhesives, and printing methods is crucial.

In this comprehensive guide, we’ll break down everything you need to know about weatherproof and fade-resistant labels, from what makes them durable to how to choose the right type for your specific application.

Labels serve critical roles in virtually every industry—from automotive to agriculture, and aerospace to marine. When labels fail due to moisture, UV exposure, or abrasion, the results can be costly or even dangerous. Faded warnings, missing outdoor asset tags, or unreadable barcodes can lead to:

Investing in durable, long-lasting outdoor label solutions helps ensure your information remains intact and readable for the full lifecycle of your product or equipment.

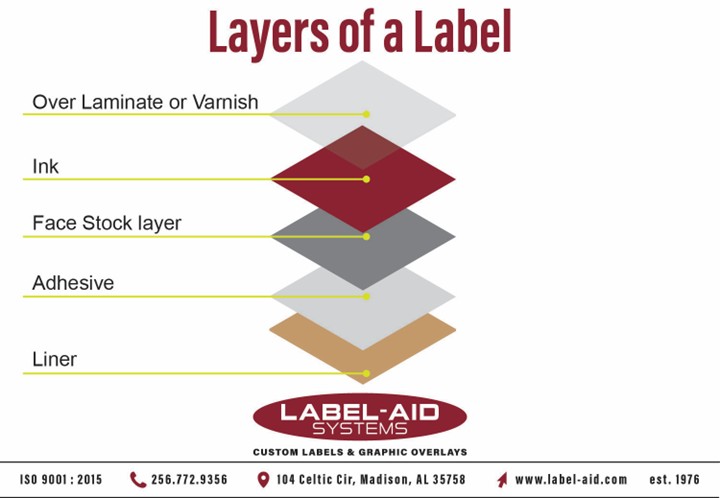

A custom label construction explicitly made to succeed in an outdoor environment

Ink film thickness refers to the depth or thickness of the ink layer applied during our printing process. The thickness of the ink has a HUGE impact on UV resistance (fade resistance).

Given this fact, for an outdoor label to last many years, screen printing is a must. In screen printing, thick ink is pressed through a mesh (or screen) to form the desired print image. This process is unparalleled in delivering thick and opaque ink to the face sheet of your custom outdoor label. This thick ink film creates the ultimate in fade resistance. Screen printing costs more because it is a slower process and also requires a screen setup for each color. Those higher costs must be weighed against the potential for failure in the field.

For labels that need to last a year or less outdoors, we can use automotive-grade pigmented inks flexographically printed, in conjunction with a laminate applied over the ink and face sheet. The laminate for outdoor applications contains special UV inhibitors to protect against weathering and UV degradation. Automotive-grade pigmented inks are specifically formulated inks containing finely dispersed pigment particles, designed to meet the rigorous demands of the automotive industry for durability, colorfastness, and resistance to environmental factors.

When designing your custom outdoor labels, consider the colors you select carefully. Red, orange, yellow, and light blues tend to fade much quicker. These colors have longer wavelengths and absorb more UV energy, which accelerates the breakdown of the pigment molecules. Black, dark blue, dark green, and other dark colors fade less quickly. It takes more pigment to make dark colors, making them more resistant to UV rays.

Laminates

We always recommend a polyester overlaminate to protect the ink from weathering, as it also contains UV inhibitors that help reduce the effects of harmful UV rays, thereby extending the lifespan of the print.

We have customers who choose not to laminate their screen-printed outdoor labels. They have performed testing and know the life expectancy of their custom labels without laminate, which saves significant costs.

Face Stocks

There are only two logical choices for true outdoor label face sheets, which are meant to withstand all elements for an extended period, and they are Polyester and Vinyl.

If you need flexibility and conformability, then vinyl is the choice.

If those are not a factor, then polyester is a very rugged choice.

Polyester Laminates and Face Stocks (aka PET, Mylar®, & Polyethylene Terephthalate)

Polyester labels resist tearing, abrasion, and most solvents. Polyester labels can withstand high temperatures up to 302°F (150 °C) or low temperatures down to -40°F (-40 °C). Polyester labels are ideal for outdoor applications due to their waterproof, weatherproof, UV-resistant, and temperature-stable properties.

Features & Advantages of Polyester Labels

Polyester is unaffected by moisture and practically impermeable to odors; polyester base materials are available in clear, white, metallized, and silver finishes. Optically clear overlaminates are also available, in gloss and matte finishes. Our Mylar labels are well-suited for outdoor applications where they may be exposed to the elements.

Vinyl Face Stocks

As a label stock, vinyl is known for its

There is only one choice for the type of adhesive base for outdoor labels: an acrylic-based adhesive. Within acrylic-based adhesives, there are various versions tailored to your specific situation.

Advantages – Acrylic-Based Adhesives

$ Vinyl Laminated, Flexo Printed (one year or less only)

$ Polyester Laminated, Flexo Printed (one year or less only)

$$$ Vinyl Not Laminated, Screen Printed

$$$ Polyester Not Laminated, Screen Printed

$$$$$ Vinyl Laminated, Screen Printed

$$$$$ Polyester Laminated, Screen Printed

Ready to Weather the Elements?

When performance matters, standard or inexpensive labels won’t suffice. Labels exposed to the elements must be engineered for longevity, resilience, and readability—no matter what Mother Nature throws at them.

At Label-Aid Systems, Inc., we’ve spent decades perfecting custom label solutions for harsh environments. Whether you’re labeling farming equipment, outdoor electrical panels, or oil rig machinery, we’re here to help you choose the right combination of materials, adhesives, and print technology for optimal durability.

Your Label. Your Environment. Your Solution. Only with Label-Aid Systems, Inc.