Medical Equipment Graphic Overlays

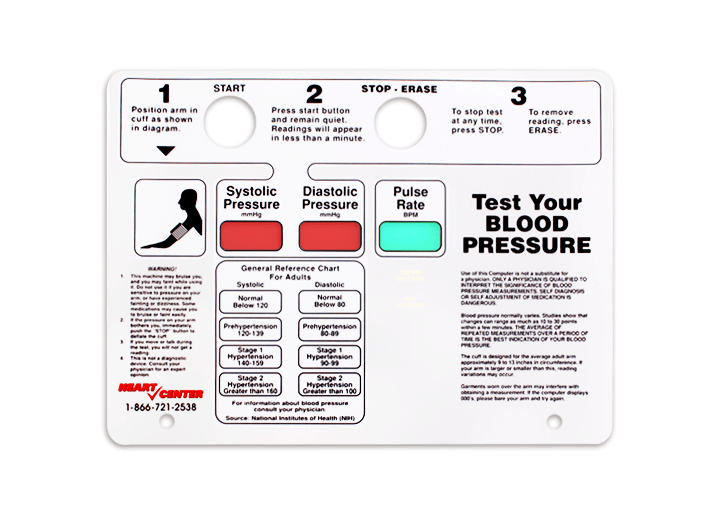

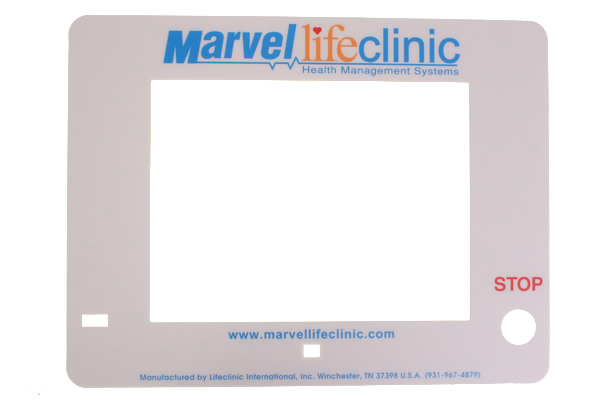

Label-Aid Systems, Inc., an Alabama-based ISO-9001-2015-certified company, manufactures high-performance medical graphic overlays. We manufacture overlays that help to identify the functions and controls of your medical devices while protecting sensitive electronic equipment underneath.

A control panel overlay for medical equipment serves as a brand identifier and improves lifespan of the equipment, but also gives the equipment an attractive outward appearance. We can make graphic overlays in a variety of colors, company logos, and cutout patterns that fit your needs. Don’t hesitate to contact us to discuss the specific requirements of your business.

Start by getting a quote in minutes from our team of experts!

Graphic Overlays Quote & Order OR Contact Us for Custom Quote