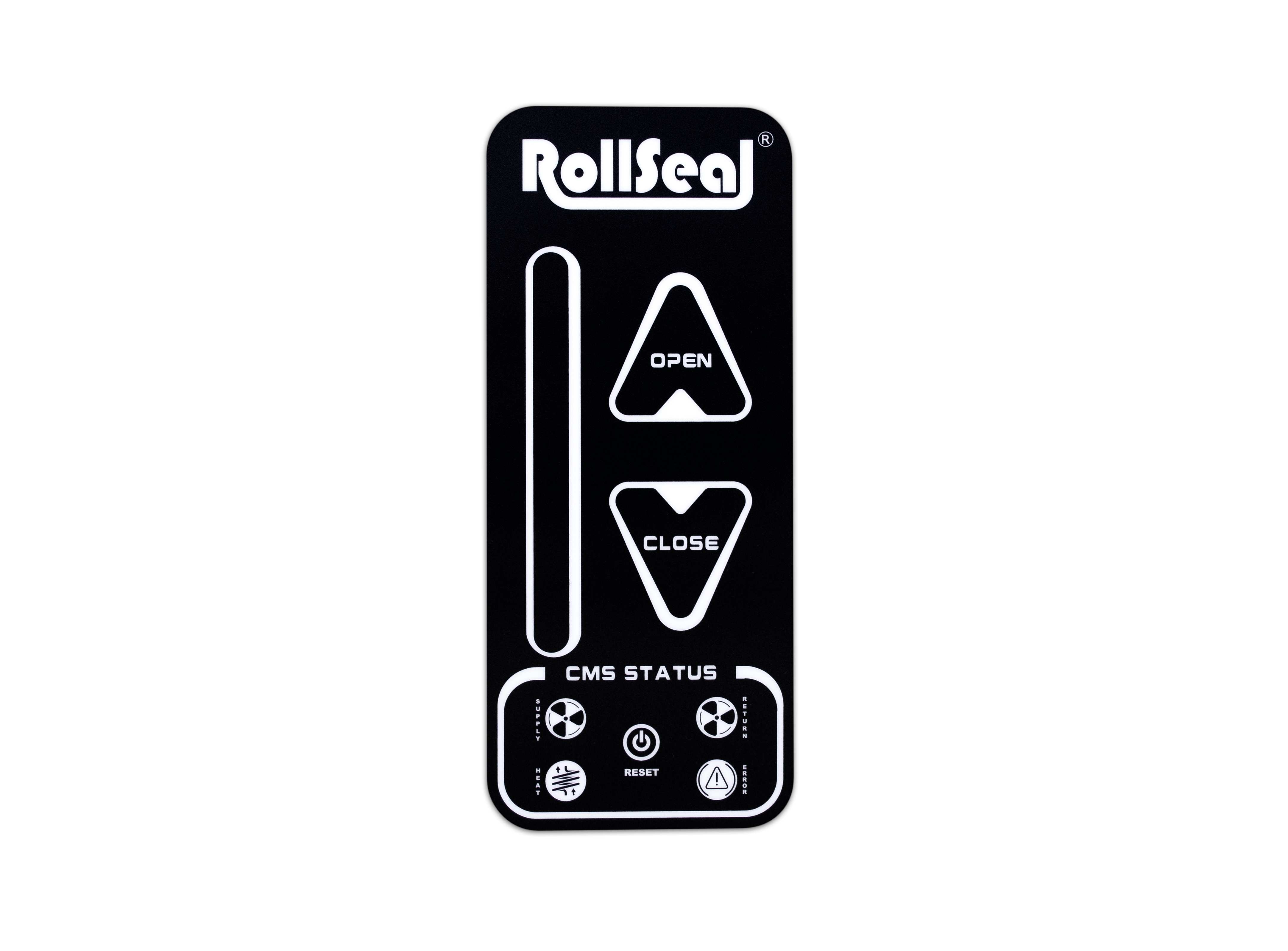

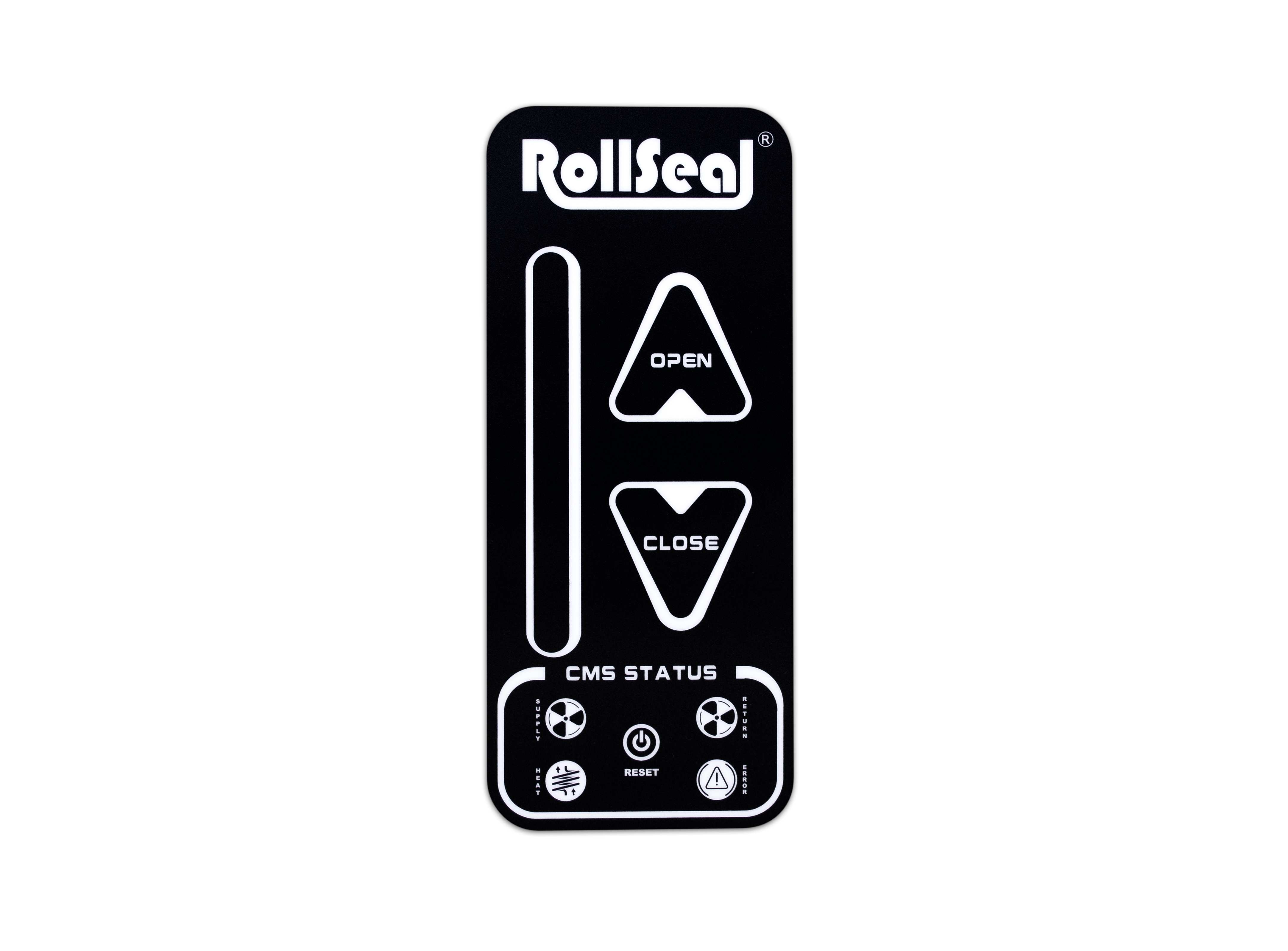

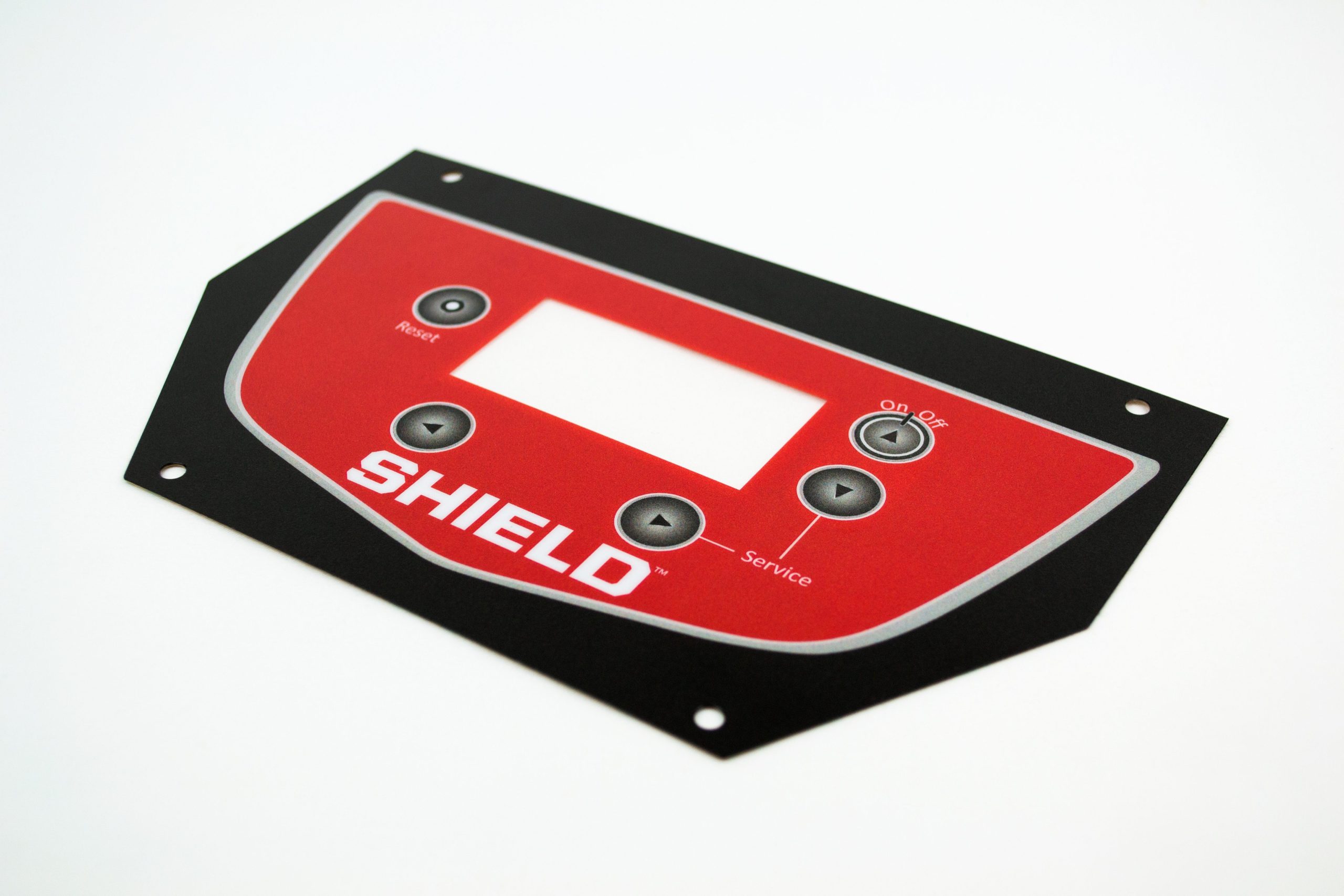

While the majority of the graphic overlays we print and construct for customers use polycarbonate as the substrate because it is less expensive, there are very specific reasons that you might choose to select a polyester substrate for a graphic overlay as a better alternative. (Some refer to polyester as Mylar, which is a DuPont tradename).

Polyester is a widely used material for graphic overlays due to its’ durable material in terms of ruggedness and fatigue resistance. Polyester is resistant to many external factors like abrasion, chemicals, temperature, and more! These properties make Polyester a great material to be used in harsh environments.

Graphic Overlays Quote & Order OR Contact Us for Custom Quote

Some of the reasons to choose a polyester nameplate substrate include:

Some applications where polyester graphic overlays shine:

There are some reasons to consider a polycarbonate overlay rather than a polyester graphic overlay. Keep these in mind when selecting your overlay material.

To order your polyester overlays, request a quote from Label-Aid today.

I have used Label Aid systems for many years now and they have been a wonderful company to partner with. They have always done great work and have delivered in a timely manner. They have rushed many jobs for me when I have needed projects expedited due to a last minute rush. The team is easy to work with and …

Our company has been using tens of thousands of Label-Aid products exclusively for almost two years now. Top quality products, responsive turnarounds, and outstanding customer service. Debbie our customer service rep is an absolute joy to work with and I look forward to our interactions. Happy customer for life here!

The people at Label-Aid are great to work with. The labels they provide our company with are always the best quality and are always delivered on time. Pricing is usually better than others. I highly recommend. Great team.