When Label-Aid Systems started manufacturing labels nearly 50 years ago, initially providing high quality labels to automotive giant Chrysler, as well as many electronics companies, we were very quickly called on to manufacture graphic overlays. Customers appreciated our attention to detail, customer service responsiveness, quality systems, expertise, and they needed a company that possessed those qualities providing them with graphic overlays as well as labels. In the past 49 years we have manufactured graphic overlays for many industries, and various products, with a large segment of our graphic overlays used in the industrial equipment sector. Many names are used referring to graphic overlays, all describing the same product: nameplate, faceplate, control panel, die cut overlay, polycarbonate overlay, OEM overlay, equipment overlay, electronic overlay, Lexan overlay, and polycarbonate overlay.

Everything we do at Label-Aid Systems, including Industrial Equipment Graphic Overlays is Custom manufactured to your desired specifications!

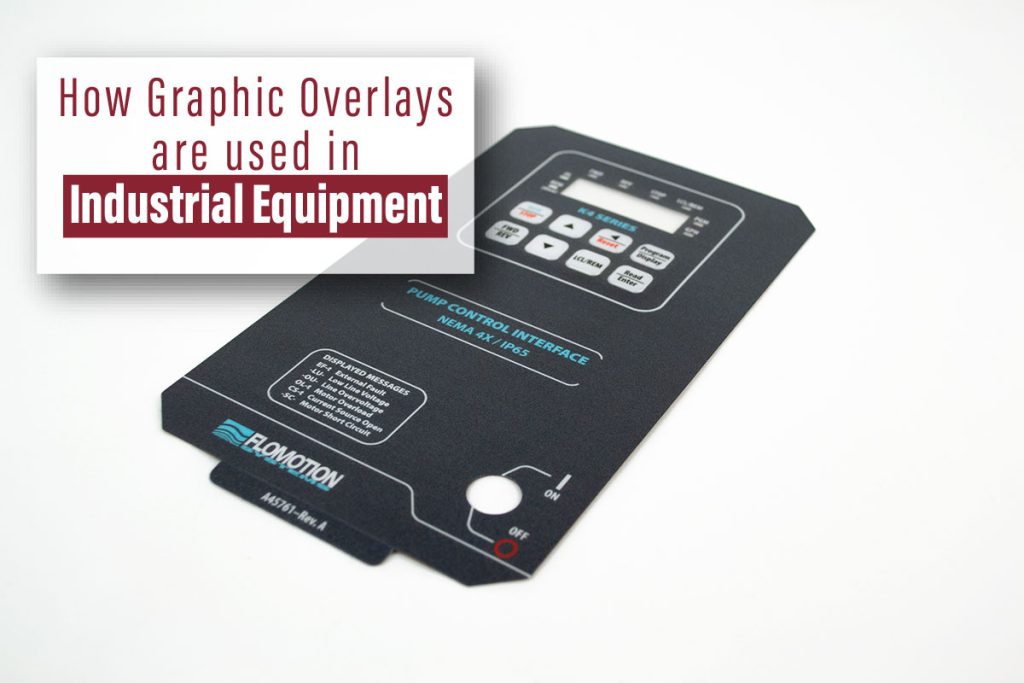

A graphic overlay is a custom printed, custom cut, piece of polycarbonate or polyester (usually) that is between 5 and 20 mils thick.

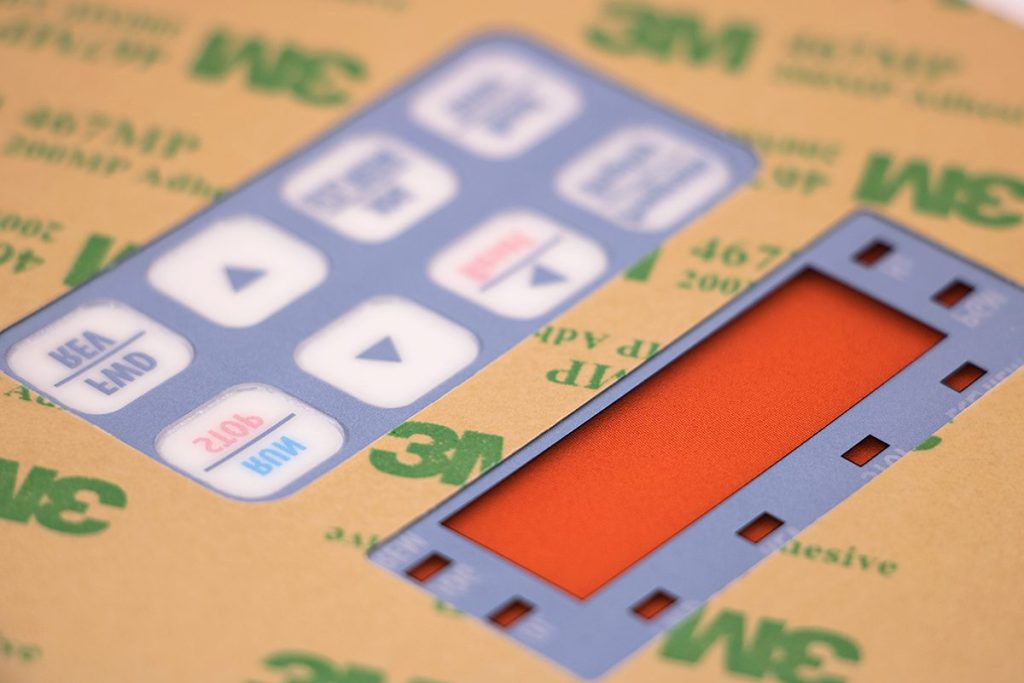

The material is clear with various textures available, and all graphics are printed on the back, so that you are actually looking through the material, to see the printed graphics. Some call this buried graphics, or second surface printing, and this makes graphic overlays very unique, in that they are not surface printed. They require no laminate protecting the graphics, since the material itself becomes that barrier. Screen inks may be used, or digital inks (explained later in this article are what factors determine which ink). Dead front graphics may also be printed, which only appear when backlit, in various custom transparent colors.

Our in-house experts help customers decide on adhesive selection, which varies depending on the application. Adhesive is applied, after the piece is printed, encapsulating, or enclosing the ink.

Overlays may have windows in them, to allow LED’s to be displayed from the equipment they are applied to. Windows may retain the texture of the material, or can be coated to be more optically clear (wet out windows).

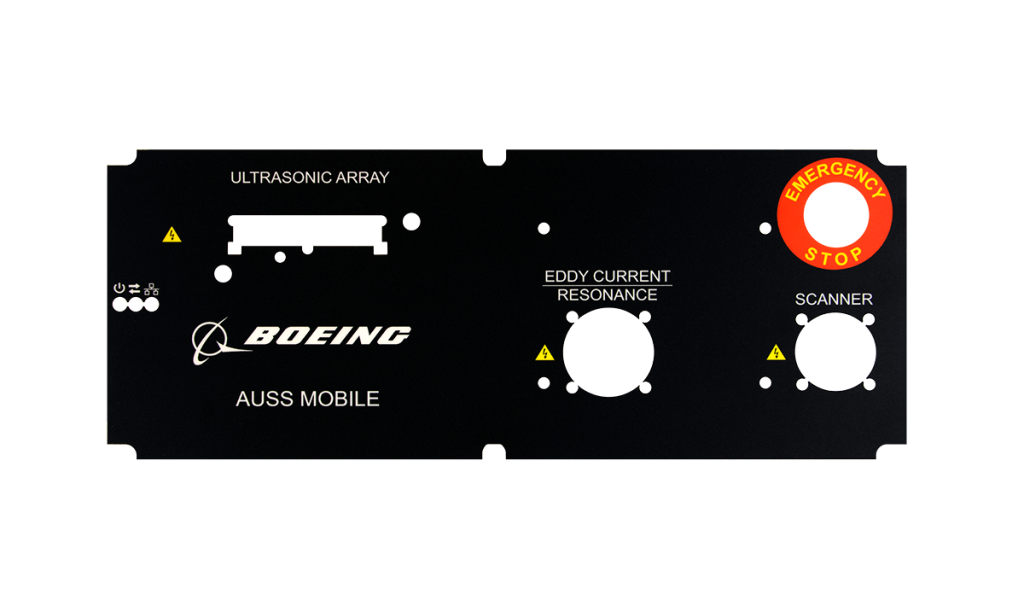

The piece is cut to the custom size and shape, using a laser or steel rule die, depending on the size of the order or the particular application. Also, holes, rectangles, plug ins, and many shapes may be cut through the overlay to fit particular needs. Embossing may be used to raise the material to better define various buttons that press or actuate an underlying switch. Users appreciate this tactile feel.

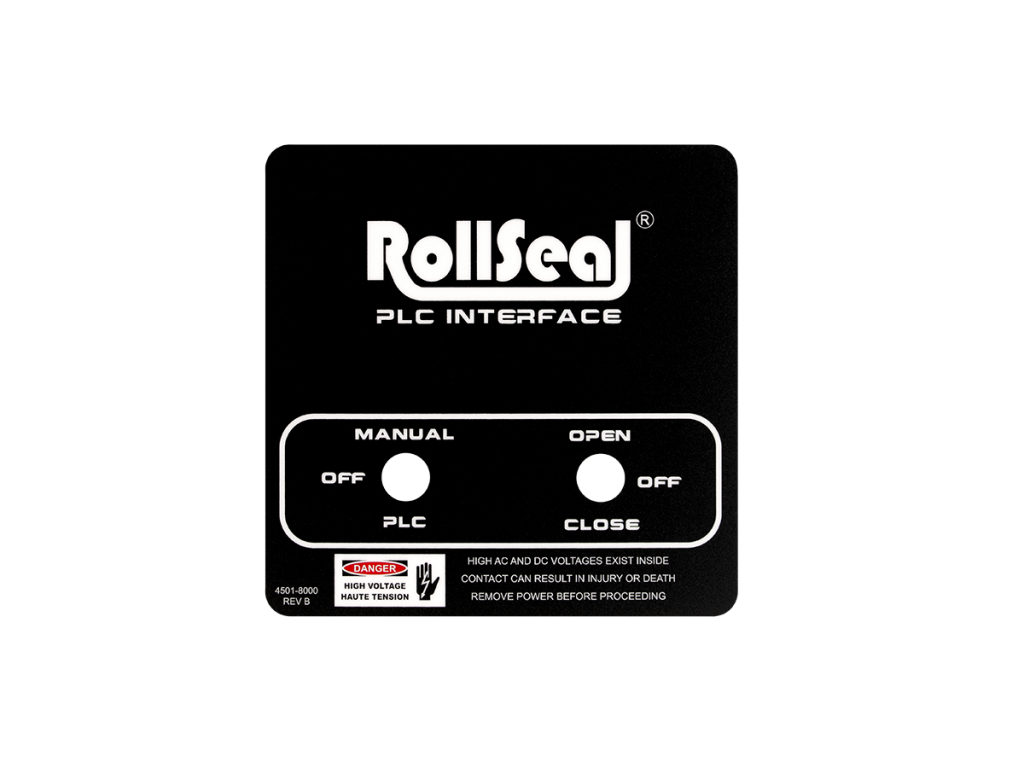

The end result is a custom graphic overlay that acts as an interface for users of the industrial equipment, as well as to instruct, warn, and direct.

In today’s high-demand industrial environments, equipment performance, operator safety, and interface clarity are mission-critical. One component that seamlessly blends functionality, durability, and aesthetics is the graphic overlay. While often considered a surface detail, industrial equipment graphic overlays play a pivotal role in the usability and longevity of machines across a wide range of sectors.

Whether you’re in purchasing, engineering, or operations, understanding the impact of graphic overlays for industrial applications can lead to better-performing systems and smarter investments.

Industrial equipment will be used over many years, so the graphic overlay, nameplate, or faceplate must last many years as well, while remaining highly legible and completely functional. Our in-house team can guide you through material selection based on your application’s environmental, mechanical, and aesthetic requirements.

Polycarbonate and polyester are very rugged materials that form the faceplate portion of a graphic overlay. A hard coating may be added to both polycarbonate and polyester, to make them scratch proof under normal conditions, as well as provide anti-glare properties. Also, coarse textures can be utilized allowing for an even longer life.

Advantages:

Disadvantages:

B. Polycarbonate (known as PC, Lexan, Makrolon, Ultem, and Valox)

Advantages:

Disadvantages:

Graphic overlays provide unparalleled durability for difficult industrial situations, not only through the use of a super tough face sheet, but also by the fact that the graphics are printed or buried BEHIND the face sheet of the top layer (second surface printing). The 5-20 mil material is a barrier itself. Cleaners can be used without affecting the graphics at all. So, hazards, warnings, emergency instructions, operating instructions, user safety and compliance information remain totally legible for the long life of the equipment in the harshest of environmental conditions. Weatherproof graphic overlays for industrial equipment that will be exposed to the elements, utilizing UV resistant materials, are available also.

When adhered to the equipment, the graphic overlay, nameplate, or faceplate acts a barrier protecting sensitive components like circuitry, LED’s, and touch sensors located beneath the graphic overlay. This prevents moisture, chemicals, dust and other contaminants from penetrating and damaging internal parts.

This is particularly critical for industries exposed to:

Second Surface Printing Ensures Operator Guidance Clarity

One of the most essential functions of a graphic overlay is providing the operator with clear and immediate visual cues. Buttons, switches, LEDs, and digital screens are often surrounded by labeled overlays that:

By using color-coded zones, icons, or instructions, overlays reduce the risk of user error—especially in high-stakes environments like manufacturing lines or laboratory instruments.

Second Surface Printing Ensures User Safety and Compliance

Industrial machinery must meet safety standards and often regulatory requirements (such as OSHA, ISO, UL). Overlays are part of a larger safety system, offering:

Graphic overlays are often required to remain legible and intact for years—making material quality and print durability essential for compliance.

Screen printing is the norm for situations where equipment will be used outdoors for a majority of the time. It provides more UV light fastness. Also, if our customer wants a true metallic gold or silver on their overlay, nothing competes with screen inks.

But we now print the majority of industrial equipment graphic overlays digitally due to its many advantages.Digital printing offers offset-quality graphics, perfect registration, unlimited serialization of data, barcodes, and QR codes, high resolution for fine vignetters, and 4-6 color process printing. The freedom for companies and graphic designers is endless with digital printing.

Beyond function, overlays offer an opportunity to reinforce branding. Logos, corporate colors, and modern design elements elevate the look of machinery—especially for OEMs looking to differentiate their products.

Custom industrial equipment graphic overlays also help integrate machines seamlessly into the client’s facility design or corporate identity. Aesthetics matter—not just for first impressions, but also for fostering trust and usability.

Graphic overlays must adhere well to industrial equipment permanently, over many years. Our group of application experts, can be very specific about the adhesive we choose, specifically for your application, since there are a great number of high-performance adhesives available to tackle the toughest applications.

Low surface energy (LSE) surfaces that normally would provide poor adhesion, can be easily addressed with the correct adhesive. Surfaces that the industrial overlay will be applied to must be made known to our team to do an expert job specifying your adhesive. Knowing surface texture, contour, surface energy, moisture, contaminants, plasticizers, temperature, and UV exposure help determine the correct adhesive.

Also, no adhesive zones may be designated on the graphic overlay where switches or windows are used.

Purchasing Considerations for Industrial Overlays

For procurement teams, evaluating graphic overlays means balancing cost, performance, and lead times. Here are some tips:

Label-Aid Systems offers in-house engineering support, quick prototyping, and turnkey production to support your team at every stage.

With over 49 years of experience designing custom overlays, and labels, Label-Aid Systems Inc. has become a trusted partner for OEMs and industrial manufacturers across North America. Here’s why:

Industrial equipment graphic overlays are a critical component in any rugged, high-performance user interface. They bridge the gap between form and function, combining durability with design to enhance usability, safety, and brand identity.

Whether you’re engineering a next-gen control system or sourcing replacement overlays for legacy machines, Label-Aid Systems Inc. is here to help with precision-crafted solutions tailored to your environment.

📞 Ready to discuss your next project? Contact our team to request a quote, consult with a design engineer, or receive a free sample kit.