Custom labels are essential in various industries, including manufacturing, medical devices, food, and beverage. Whether you’re marking components for traceability, providing safety instructions, labeling a medical device, or enhancing shelf appeal, the quality and functionality of your custom labels directly impact your product’s performance and brand perception. But when it comes to custom labels, one thing often surprises buyers: costs can escalate quickly if not carefully and thoughtfully managed.

At Label-Aid Systems, we believe you shouldn’t have to compromise between quality and affordability. With 50 years of experience producing custom product labels, durable labels, graphic overlays, and industrial nameplates, we’ve learned how to help customers reduce labeling costs without sacrificing performance. Everything we manufacture is custom, whether a custom label or custom graphic overlay. We are the custom label experts! Let us help you navigate the many options to maximize the value of your custom labels.

This guide outlines strategies and best practices that can help you cut expenses—and still get labels that work hard for your brand.

1- Thoughtfully Consider Your Product/Custom Label Longevity and Environment

2- Know All Custom Label Construction Possibilities and Their Costs with Your Product in View

3- Leverage Quantities Needed to Reduce Your Costs

4- Allow Us to Help You Determine the Printing Process and Evaluate Economics

Longevity

There is a significant difference between a product that will fly off a retail shelf and be disposed of immediately and a custom UL label that will be adhered to an electrical product for many years, requiring the ultimate in durability. A custom water bottle label has a shorter life span compared to a custom asset label, which must last as many years as the asset is in use. The product life of the item labeled is a massive consideration in choosing a label construction that makes sense for your budget. Long-lasting, extremely durable custom label constructions for your product cost more than those that have a short life span, such as a box label. At Label-Aid Systems, we want to help you meet your longevity requirements at the most economical cost. Let us be your custom label consultant!

Environmental Conditions

Answers to these questions help us to specify the best custom label for your money:

We strive to meet your requirements, but not overbuild your custom labels, which cause extra costs that you certainly don’t need.

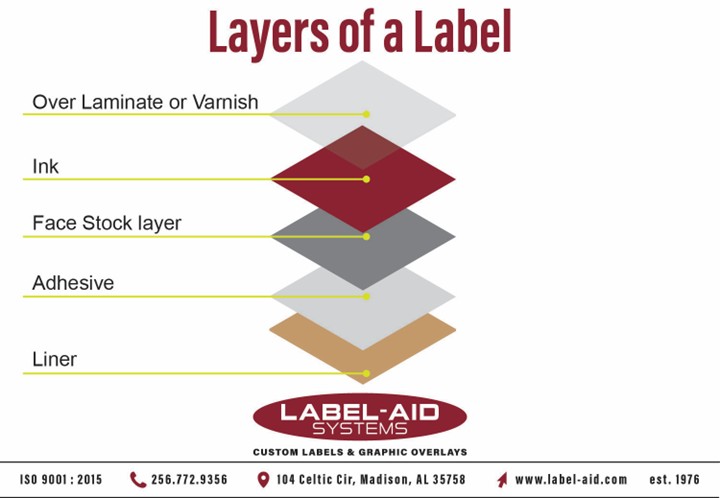

Your custom label for your product consists of multiple layers. Viewing it from the top down, those layers are:

No Laminate or Varnish

If your product label is not exposed to moisture, liquids, solvents, abrasion, weather, UV light, or cleaning agents, you may opt for no laminate or varnish at all. This will certainly save you money. We help customers select this option if their product will be used quickly and discarded and is in a moisture-free environment. Additionally, if the custom label is applied to a product that is always kept indoors, this may be a good option to reduce the cost of your custom labels. Custom product labels like box labels, inventory rack labels, some electronics labels (inside a protective box), printed circuit board labels, and quick turn prime product labels are candidates for reducing the cost of your custom labels by eliminating a protective laminate or varnish.

Do not laminate or varnish your custom label unless necessary. It will save you money!

Many of our customers want to use a thermal transfer printer at their location to add additional information to their custom labels, like barcodes, serial numbers, and variable data. A thermal transfer printer uses a wax or resin ribbon and melts an image onto the label material. While you will achieve the absolute best adhesion between thermal transfer ribbons and label materials specifically designed to accept thermal transfer printing, we can often help you specify a ribbon that will adhere to less expensive stock (not specifically made for thermal transfer printing). Testing whether the particular label stock that makes the most sense economically for your application will accept thermal transfer printing and adhere properly can be easily done, saving you money. Please let us help!

Varnish

A varnish is a clear liquid coating applied to the face sheet of your custom label, which is cured by high-intensity UV lighting as it runs through our label presses.

Varnish will provide some moisture, solvent, and abrasion resistance for your custom labels. Varnishes typically lack UV protection, making them unsuitable for outdoor applications.

A basic UV Varnish is less expensive than any laminate. If some moisture and abrasion resistance will suffice for your indoor product label, this is an option that can save you cost.

If you want a robust varnish that provides more moisture resistance, it will cost as much as a BOPP (Biaxially Oriented Polypropylene) laminate. The BOPP laminate will offer better protection than varnish and does and not cost more than an advanced varnish.

Varnishes come in a variety of finishes, including gloss, matte, and satin. Varnishes can be applied to the entire label face, or for an eye-catching look, can be applied to any portion of your custom label that you like and in any shape you wish. This is called a spot varnish. For marketing purposes, if you would like to draw attention to a specific feature on your label, you can achieve this by providing contrast using a spot varnish. A glossy label could be contrasted with a matte spot varnish, or a matte label could be contrasted with a glossy spot varnish. This can help to give your labels an unusual look and set you apart from your competition at a modest cost. This costs less than other methods for differentiating your product.

If your custom label needs to be imprinted with a thermal transfer printer at your location (barcodes, UPC Codes, serial numbers, QR Codes), and the label face sheet is not thermal transfer imprintable, and you wish for maximum adhesion of the thermal image, we can add a spot varnish to your label in the location you wish to print that information. This can save cost over selecting a thermal transfer imprintable stock when you need only a limited area to accept imprinting.

Examples of products that might fall into the category of using a varnish on their custom labels are:

Laminates

Laminates, or overlaminates, as some refer to them, provide much better protection than varnishes.

We offer three different categories of protective laminates for your custom labels:

1- BOPP Laminates (Inexpensive)

Using BOPP laminates to protect less expensive face sheets is an effective way to reduce the cost of your custom printed labels.

We frequently encourage customers to select an inexpensive face sheet, such as paper or BOPP, and laminate it with BOPP for protection. This allows your indoor custom labels to be protected from moisture, oils, cleaners, solvents, and abrasion when needed. Other label materials might be overkill and drive up your cost. We are sensitive to this. BOPP limits your expenditure while providing a great, versatile, and durable label. BOPP has some very limited UV inhibiting qualities. For this reason, we do not recommend a BOPP laminate for most outdoor applications, nor for any applications that involve direct sunlight. Photo-oxidation begins to occur rapidly in direct sunlight, and then humidity accelerates this process, causing BOPP to become brittle and crack and break down. BOPP also may yellow in direct sunlight.

You can select BOPP in both glossy and matte versions, suitable for the aesthetic you desire for your custom labels and products. If you need to add thermal transfer printing to your label, you can choose the version of BOPP laminate that allows for maximum adhesion with thermal transfer ribbons. If you do not need thermal transfer imprinting, you will save dollars on your BOPP laminate.

2-2- Polyester Laminates (Expensive)

Polyester laminates for custom labels offer the ultimate in durability, albeit at a higher cost. It is solvent-resistant, abrasion-resistant, tear-resistant, and exceptionally clear. There is an outdoor version of polyester laminate with UV inhibitors that provides fade resistance for the inks it covers, as well as waterproof and weatherproof functions.

If your product must last for many years, either indoor or outdoor, and will be in an environment where your end product and its custom label, must be cleaned often, or is exposed to solvents or other contaminants, this is a great option. We noted that the product is expensive, but you can opt for a polyester material with polyester laminate, and this label construction is less costly than using polycarbonate or a graphic overlay. Some opt for a polyester label construction rather than a graphic overlay if the functionality is not needed, which can reduce your costs greatly.

Remember, this is more expensive than paper with no laminate, paper with a BOPP laminate, or BOPP material with a BOPP laminate. Quickly consumed and moderate-use products don’t need this type of durability for their custom labels. Please consult with us. Let us put our nearly 50 years’ worth of experience to work for you. We exist to meet your needs and save you money.

Please refer to our custom polyester label page for the types of products that need this durability.

3- Polycarbonate (Very Expensive) in a Velvet Finish (Textured Surface)

This is even more expensive than polyester. It is thick (3 mils) and very textured. When our customers request extremely long runs of graphic overlays, we discuss with them if this might be an option, given their design, since the end product looks like a graphic overlay but is not as thick. Sometimes, more thickness is needed, or more holes are required than can be practical to die cut on a roll press. However, if those options don’t exist, this option can save a significant amount of money on long runs.

Please refer to our polycarbonate material page for information on the benefits and applications of polycarbonate material. (same benefits for laminates as materials)

We have a main material page here. It links to all the individual material pages for face stocks. We won’t repeat all that information in this blog, but will provide links to it below, and you can view a guide to the costs of the materials. We are thrilled to have the opportunity to consult with you and provide the best and most economical solution for your custom labels.

Inexpensive

Moderately Expensive

Expensive

Very Expensive

Answers to questions about your end product to be labeled help us to determine the best label material (face sheet), as well as adhesive. Those questions appear below in the adhesive section.

Another area of cost is the adhesive selected for your custom labels. Most of our customers are not adhesive experts, but we are! Please allow us to help you select the correct adhesive, considering your product’s surface and the environment in which it will be used. We will not “over-specify” your custom label, adding extra costs that are unwarranted for your particular application, and ultimately save you money.

Occasionally, we have requests from those who want the thickest adhesive possible for their custom labels, regardless of their application. They reason that it will certainly stick better. While that may be true, it is also costly and may be completely unneeded. Let us help you save costs!

Knowing everything about the surface of your product to be labeled, and the environment it will encounter, allows us to put our knowledge to work for you. If we can get answers to these questions, we can save costs and completely meet all your labeling requirement needs regarding both material face sheets and adhesives:

What is the surface of the product or equipment you are labeling? Are there any past labeling issues?

What is the texture of the surface that will be labeled? Rough, smooth, somewhere in between? Any past labeling problems?

Does your product to be labeled have any contours? Is it a tight circumference? Can we get a sample or a drawing? Any past problems?

Will surface contamination be present on what is to be labeled? (solvents, chemicals, plasticizers, moisture, dust, particles…) Any issues in the past?

Is your product an indoor or outdoor product? How much direct sunlight? What temperatures will exist? Direct exposure to the elements? Any past issues related to temperatures and UV exposure?

These are the most common label adhesives that we find fit most applications and a general guide to costs:

Least Expensive:

Moderately Expensive:

You can find information about the various adhesives that are available and how they fit certain applications here. The pointof including a blurb in this blog about adhesives is that savings can be found in knowing the details of your custom label application.

An extremely thin coat of silicone is applied to the liner substrate (paper or film), which allows for your custom labels to release from the carrier liner and be applied to your product. Knowing your application can help us help you to save dollars.

We use 3 basic types of “release liners” the most:

Paper (Least Expensive)

This is the most economical option. If your custom labels are hand applied, (hand applied means that you remove your custom labels from the liner by hand and place it on your product by hand), this option will always save you money, and there is no need to look at other options. We also often recommend a silicone-coated paper release liner for many machine or automatically applied custom labels, as long as it is not a wet application (beer, beverages). Silicone-coated paper release liners are versatile, and a money-saving choice!

Poly-Coated Paper (Midrange)

Silicone-coated polypropylene on top of paper liner is thicker and more robust for some wet applications and higher speed automatic applications.

PET (Expensive, But Costs are Coming Down)

A silicone-coated PET (polyester) liner is the ultimate for high-speed applications because it is strong and will not break easily. Also, for wet applications, this works well.

Before you lock in on the size of your custom label, and drawings are made, and approvals are completed, think carefully about label SIZE. Obviously, a small label costs less than a larger one. Can you effectively communicate what you wish to with a smaller label? Are there unnecessary borders around your label that could be eliminated easily, shrinking your label without changing the look you wished to achieve? Label size reduction always creates savings!

Ink coverage is simply the amount of ink applied to your custom label’s surface. It may be expressed as a percentage. 100% coverage indicates the entire label is covered by a single color. The ink coverage amount for your custom labels affects the cost of all printing processes whether digital, flexographic (flexo), or screen printing. The more ink coverage, the higher the cost. So, if you can achieve everything you wish to achieve with your custom labels, without heavy ink coverage, it will save you money. For instance, rather than having a background color behind your type and images, you might choose for the stock to be the background (white, silver, etc.…). This will save dollars.

Also, in flexographic and screen printing, the number of colors affects cost, regardless of the amount of ink coverage. Flexo label printing must have a separate plate for each color. Screen printing must have a separate screen for each color. There is set up time for these plates and screens, registration time, and added scrap as well. Are you able to limit colors? If so, this will save on your custom label cost for flexo and screen labels.

Tooling to cut your custom labels into the shape you desire is a one-time charge for each new size and shape. We charge the customer what the tooling costs us, with no markup, and that saves costs. We have thousands of tools in stock since we have been in business for 50 years. If we have the exact size in stock, we will notify you, and there will be no charge for tooling. For shapes that are not special (ovals, squares, rectangles, and circles), we will inform you of the closest size we have in stock, allowing you to use it without charge.

It is important that we know the quantity of custom labels you anticipate using in a given period (month, quarter, or year). That will dictate what type of tooling we purchase to cut your labels. Smaller quantity runs don’t require the same type of die steel as long runs do. Let us help you save on your label budget!

The quantities you order of your custom labels play a huge role in determining your cost per label. This is especially true in flexo printing and screen printing.

Answers to the following questions about the quantities of labels ordered will help us save you money on your custom label piece price:

If you can give us the overall picture of the types of labels, their sizes, and quantities, we can help save you money!

Allow Us to Help You Determine the Printing Process and Evaluate Economics

We have written a blog that you can find here, which compares all 3 of our printing processes and the advantages and disadvantages of each process. Also indicated in this blog are the cost savings of each process, given the type of custom labels that best fit each process.

Reducing the cost of your custom labels doesn’t have to mean accepting inferior performance. With strategic choices and an experienced label partner, you can simultaneously lower costs and improve reliability.

Remember:

Whether you’re sourcing safety labels, medical device overlays, or product branding decals, Label-Aid Systems is here to help you navigate the options, optimize your specs, and reduce costs with confidence.

Ready to reduce your labeling costs? Contact Label-Aid Systems today to schedule a free consultation or request a quote.