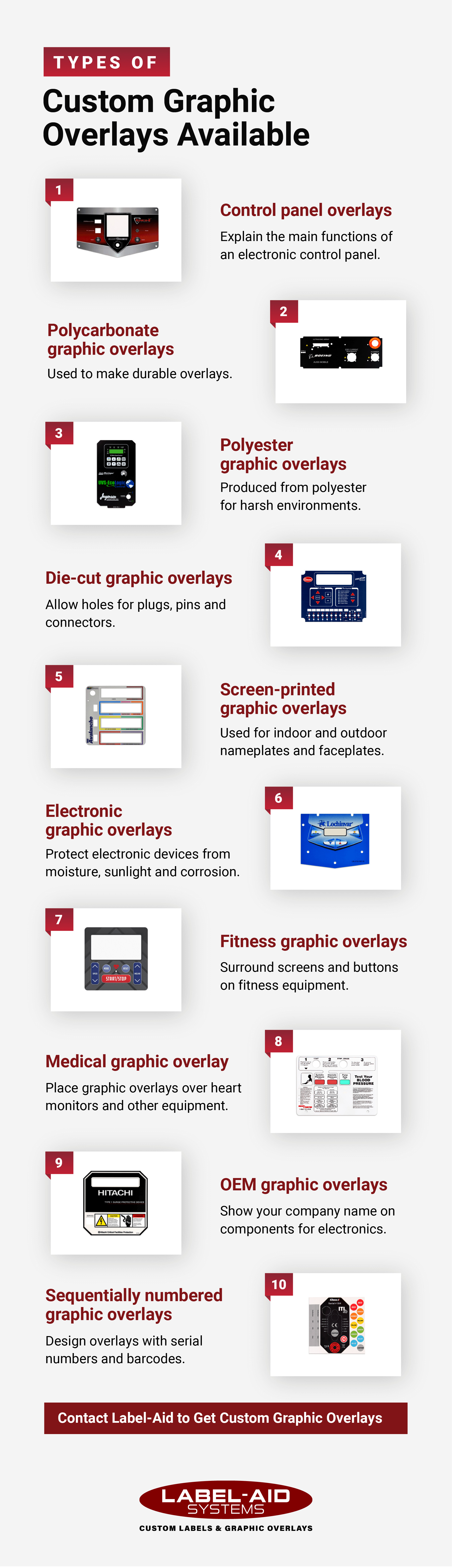

Graphic Overlays

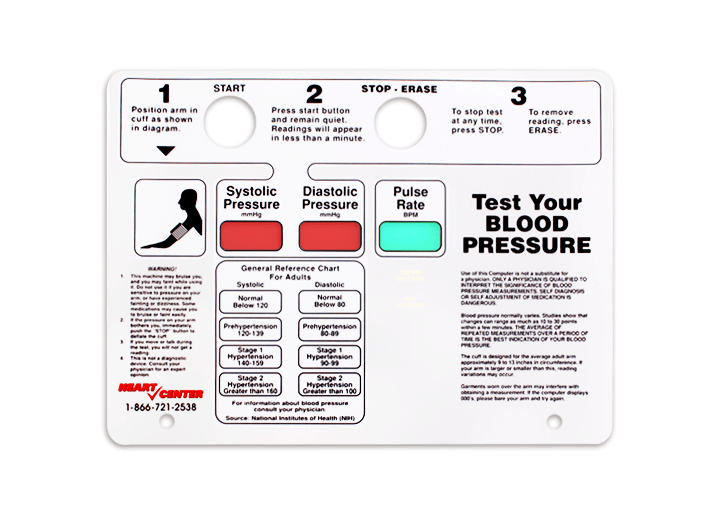

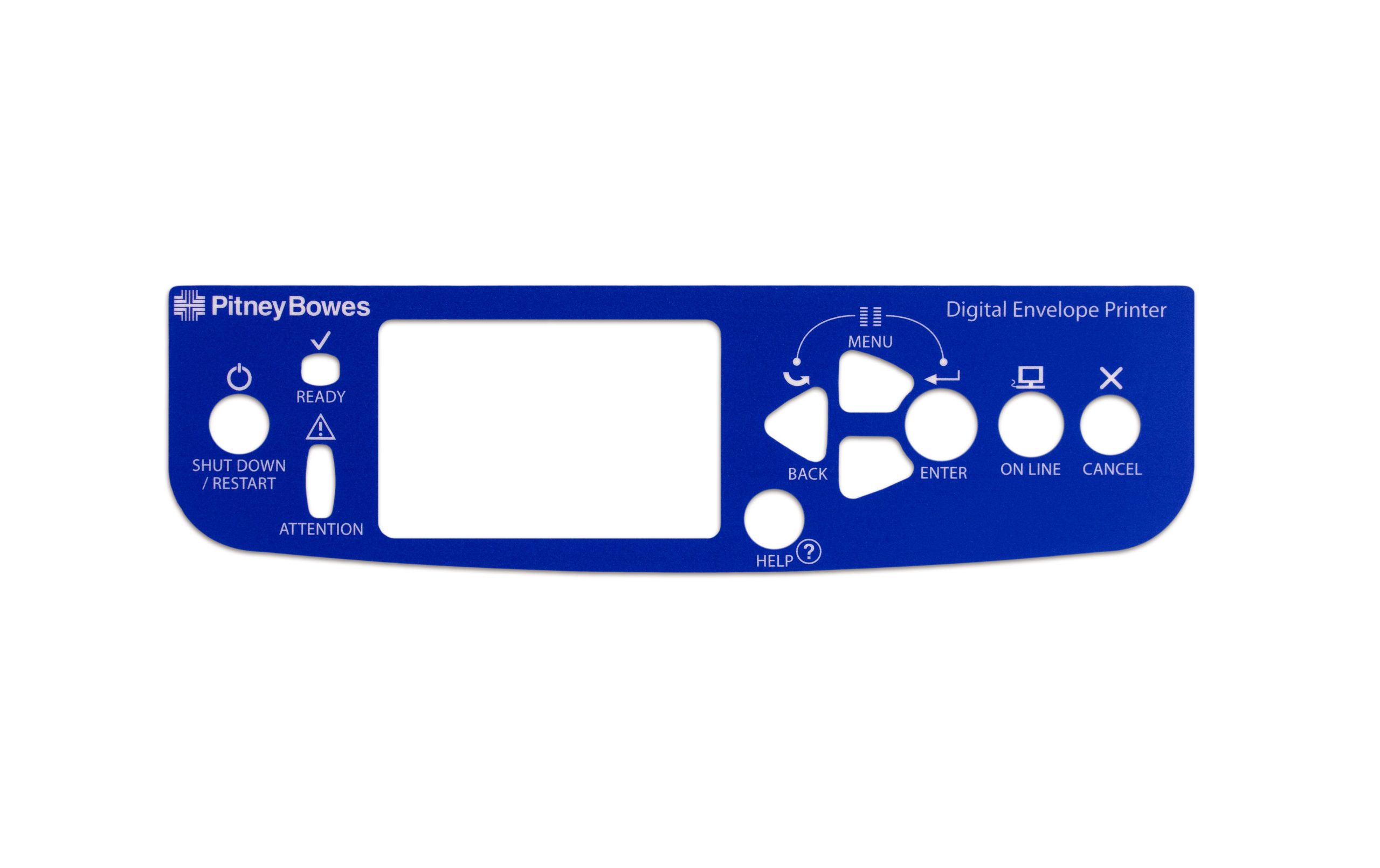

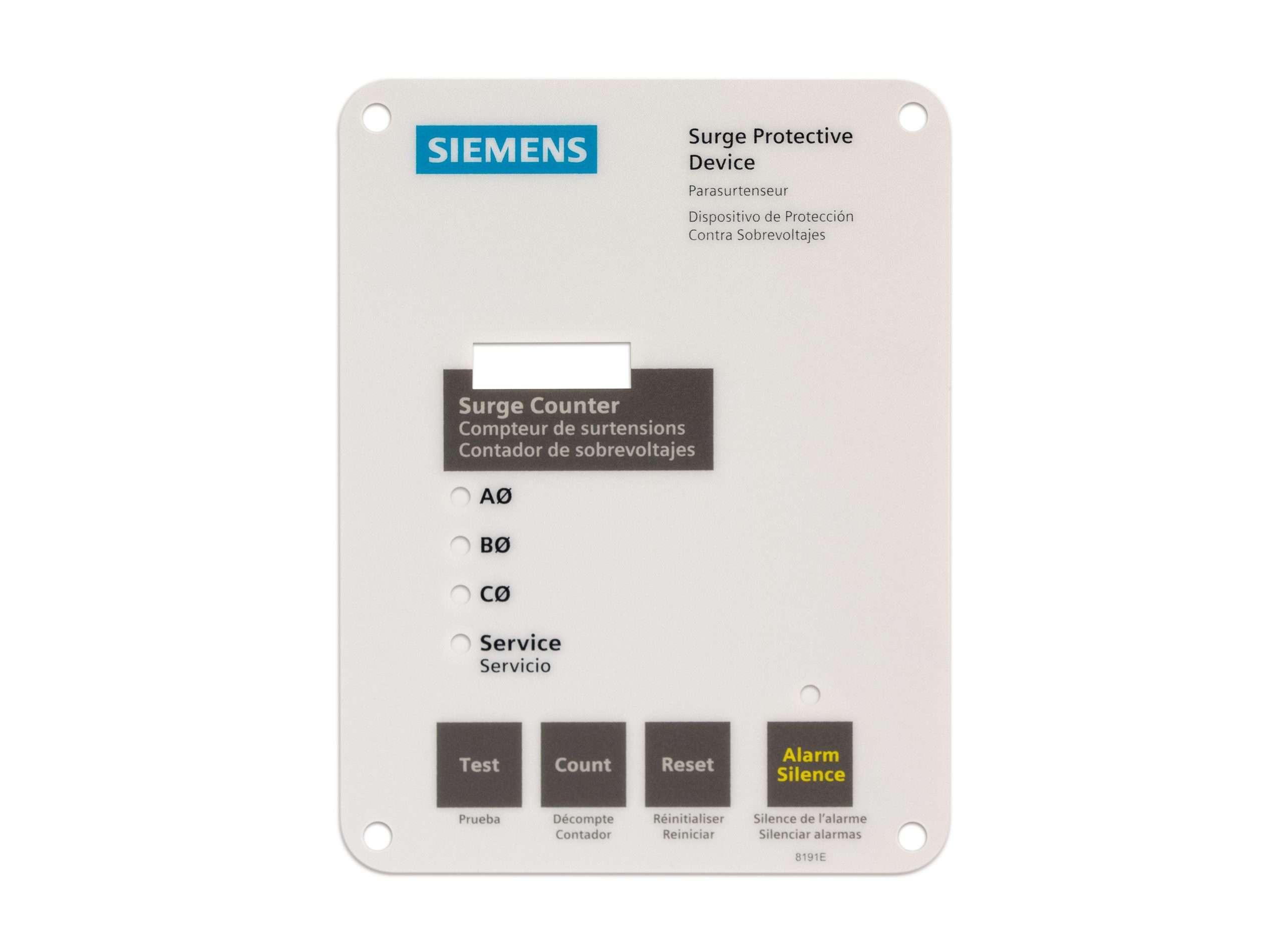

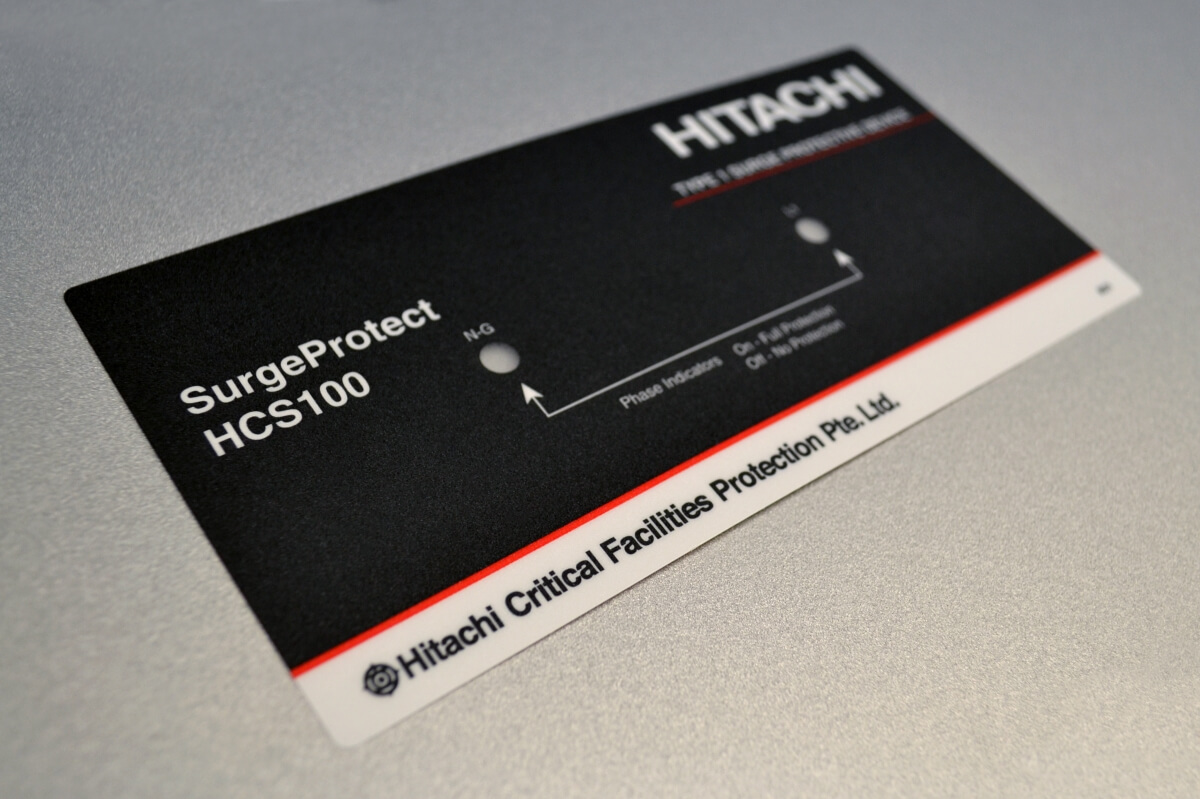

Used as brand identification on OEM electronic boxes, equipment, and machinery, custom graphic overlays are ideal for rugged environments where durability and long-life is a must. Label-Aid Systems graphic overlays and custom faceplates are a versatile, eye-catching way to identify your brand while providing information necessary to the end-user. In addition, our graphic overlays are manufactured to your specifications and are ideal for indoor, outdoor and all harsh environments.

For Fast and Immediate Service call us at (866)937-1125 or fill out our RFQ Form Now!

Properties of Graphic Overlays

Our graphic overlay properties include:

- Top substrate: The top substrate is made of polycarbonate or polyester between 5 mils and 30 mils thick.

- Subsurface ink graphics: We color-match the ink graphics using the latest computer technology. Subsurface printing protects the graphics from top-surface abrasion, weathering, UV damage, and contamination from dust, chemicals, moisture, grease and spills.

- Die cutting: Our expert die cutting stays within critical tolerances for the utmost precision.

- Applied adhesive: We custom-select the adhesive for each overlay for the best surface adherence.

Label-Aid Systems, Inc. makes graphic overlays and front panels from various hard-coat, scratch-resistant materials. We can add UV inhibitors to the material so the label lasts longer in applications that are outdoors or have lots of light. Our options include:

- Polycarbonate: Polycarbonate is a cost-effective material with clear, polished, matte and velvet textures. It’s durable and can withstand harsh conditions, like UV rays, chemicals and heat.

- Polyester: Polyester — or PET or polyethylene terephthalate — is a versatile, high-performing product that’s stable and durable in various environments. Compared to polycarbonate, polyester is more durable and resistant to chemicals and cracks, allowing for more actuations.